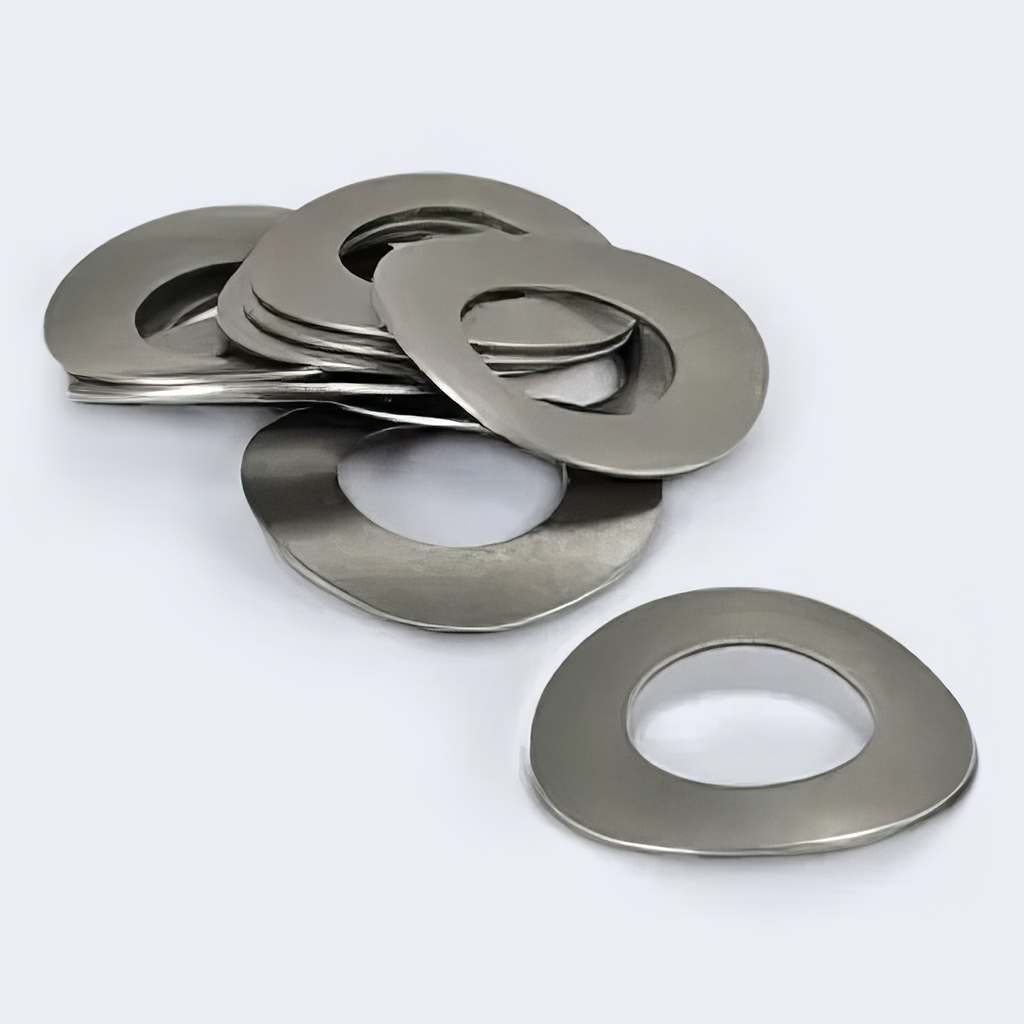

Spring Washers

Elyria Spring & Stamping offers you custom spring washers with quick turnaround and at a competitive price.

With the trend toward miniaturization and compact design, spring washers, sometimes referred to as stamped washers, are often the solution. They allow both space and weight advantages over wire springs and, when compared on an installed cost basis, they are often more economical to use.

Configuring your spring washers offers even higher load support and flexibility with deflection.

- To Increase Load – stack spring washers in parallel (in the same way). A single spring washer has a specific load for a given deflection; two washers stacked in parallel yields double the load of a single washer for the same deflection; three washers yield triple the load, and so on.

- To Increase Deflection – stack spring washers in series (opposite each other). Two spring washers stacked in series yields double the deflection of a single washer for the same load; three washers yield triple the deflection, and so on.

Elyria Spring & Stamping offers custom washers in a variety of sizes and materials including:

- Belleville Washers

- Curved Washers

- Wave Washers

- Finger Washers